- Home

- Mevotech Hub Assemblies

Mevotech Hub Assemblies

Categories

Mevotech Hub Assemblies

Call Toll Free 1-800-265-5787

Mevotech Hub Assemblies

Overview

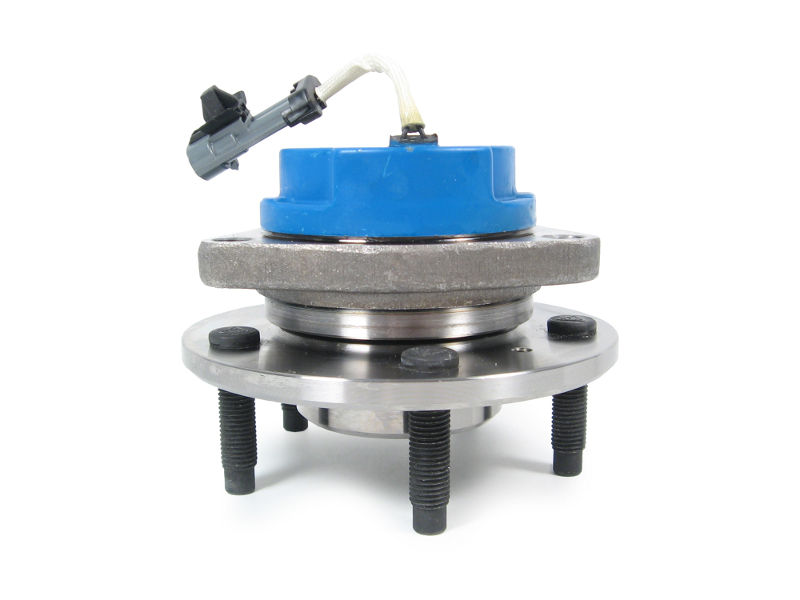

More and more vehicles today are using hub assemblies. Hub assemblies are attached to the spindle or steering knuckle and the tires are fitted over the wheel hub which turns as a complete unit with the drum or disc brake. Hub assemblies are sealed at the factory and don’t require maintenance.

Hub assemblies are an essential automotive component and must be in good working condition. All hub assemblies control the position and reduce the resistance of your wheels in contact with the road. Wheel positioning determines a number of performance aspects, including tire wear, braking control, vehicle stability in both straight lines and in turns, and overall vehicle handling.

Types

- Driven – Driven hub assemblies are required to transmit rotational torque to propel the vehicle. Driven hub assemblies are only found on Wheel End’s that are driving. An example would be for a front wheel drive (FWD) vehicle the engine drives the front wheel only, and in this case only the front hub assembly will be a driven type hub assembly.

- Non Driven – Non-driven hub assemblies are attached to all the wheel ends that do not required to transmit rotational torque. For a rear wheel drive (RWD) vehicle the front wheels are not driven because the vehicle is propelled by the rear wheels only.

Generations

- Generation 1 - First generation wheel bearings are used on many applications due to their compact design, featuring lifetime sealing and lubrication.

- Generation 2 - This second generation of hubs is compact, maintenance-free and is not only cost effective but also has an integrated mounting flange. Generation 2 design features a factory-set preload and they are easy to install – bolted directly to spindle.

- Generation 3 - Nowadays automotive manufacturers make all the efforts to improve the vehicles handling and performance by reducing their weight and complexity. Generation 3 hub assemblies provide many advantages over previous designs. Once installed, the integrated flanges of the G3 designs allow for low axial run-out and internal bearing integrity will not be compromised.

Purpose

Hub Assemblies and bearings allow the wheel and tire assembly to turn freely around the spindle, in the steering knuckle, or in the bearing support. They are also designed to handle combinations of radial and axial thrust loads Mevotech Wheel bearings are lubricated with high pressure, high-temperature grease. This allows the bearing to operate with very little friction and wear. A hub unit bearing is pre-set, pre-lubricated, sealed and requires no maintenance.

Technology

- Heavy Duty Integral Raceway - reduces vibration and increases stiffness, extending the product life and improves the overall performance

- Oversized Ball Bearings - the hubs are able to carry extra load, maximizing their life span

- O.E.M. Specification ABS Sensor and Plug - ABS sensor is internally mounted in the hub assembly and follow the OE style for a proper signal and connection

- Performance Sealing - ensures the maximum protection from road hazards and debris and minimises the risk of potential damage

- Maintenance Free - hubs are designed as a integrated system, greased and sealed for the life of the unit

Any vehicle that has ABS (Antilock-Braking System) requires an ABS sensor to determine when the system needs to be activated.

On some front wheel drive cars, the wheel speed sensors are integrated into the hub assembly. A toothed ring in the hub assembly rotates past the tip of the wheel speed sensor. This sensor provides the wheel rotation speed to the ABS computer for proper ABS function.

Loading... Please wait...

Loading... Please wait...